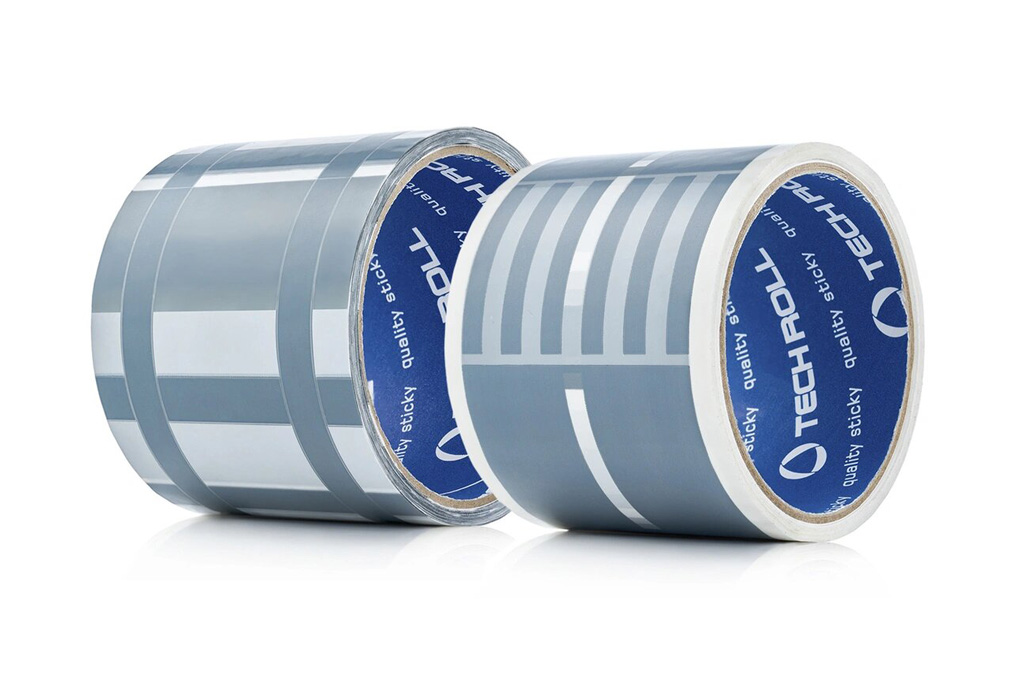

Aluminum adhesive tape

Base: aluminum foil with an adhesive applied to one of its sides, protected by an additional insert (protective layer).

Purpose: reliable connection-heat resistance, used for the installation of ventilation ducts and pipes, for sealing joints when installing refrigeration equipment and air conditioners.

Aluminum adhesive tape (AL tape) will help create a strong and durable protective layer with high moisture, steam and fire resistance for objects of various shapes and sizes. The tape has a thin aluminum base (foil) and a highly adhesive adhesive layer.

Main features of aluminum adhesive tape

AL tape is usually produced from 5 to 1000 mm in width. The length of the tape in rolls can be any.

Belt characteristics:

- color: gray;

- base material: aluminum foil;

- adhesive composition: rubber glue;

- total tape thickness: 40 to 70 microns.

There are requirements for the preliminary preparation of the surface for pasting with AL tape: it must be dry and degreased. Compliance with this requirement guarantees high strength of the resulting joint and prolongs the life of the tape.

Features and applications of aluminum adhesive tape

The main difference between AL tape is to provide protection against direct fire (it does not burn), resistance to aggressive substances and UV radiation.

The main area of application of the AL tape is the installation and maintenance of climatic equipment, construction work and the automotive industry, the areas of repair and maintenance of cars and special equipment. Aluminum adhesive tape is also used in plumbing and electrical installations.

For all of these applications, AL tape provides high strength joints and surface coatings to protect against external hazards.